Recycle Foam

Mar 7, 2022

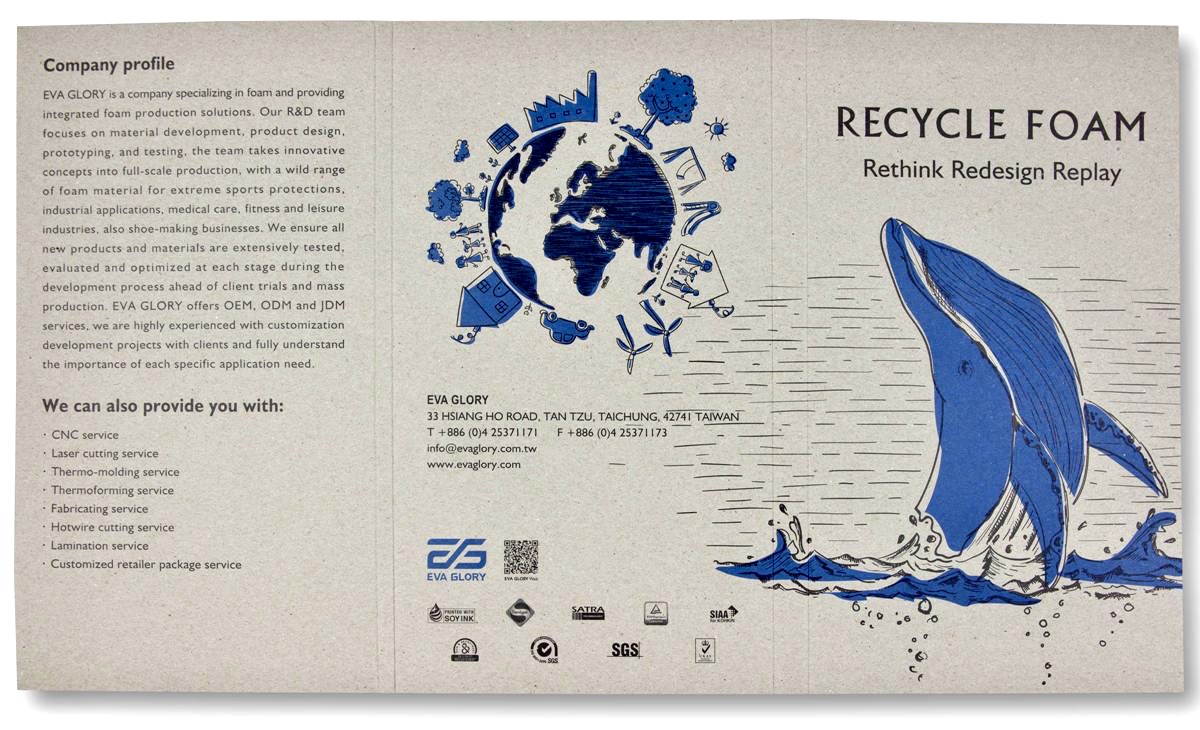

RECYCLE FOAM

The ldea (Rethink Redesign Replay) of Recycling Foam

Rethink

Changing the final life of the product/foam (e.g. landfill, incineration), and achieving the goals of environmental protection and CO2 emission reduction.

Redesign

Establishing a closed-loop foam material recycling cycle that contributes to the sustainability, safety, and balance of the environment.

Replay

Through creative and innovative upcycling approaches, to create new recycling foam products of higher quality and value than the original.

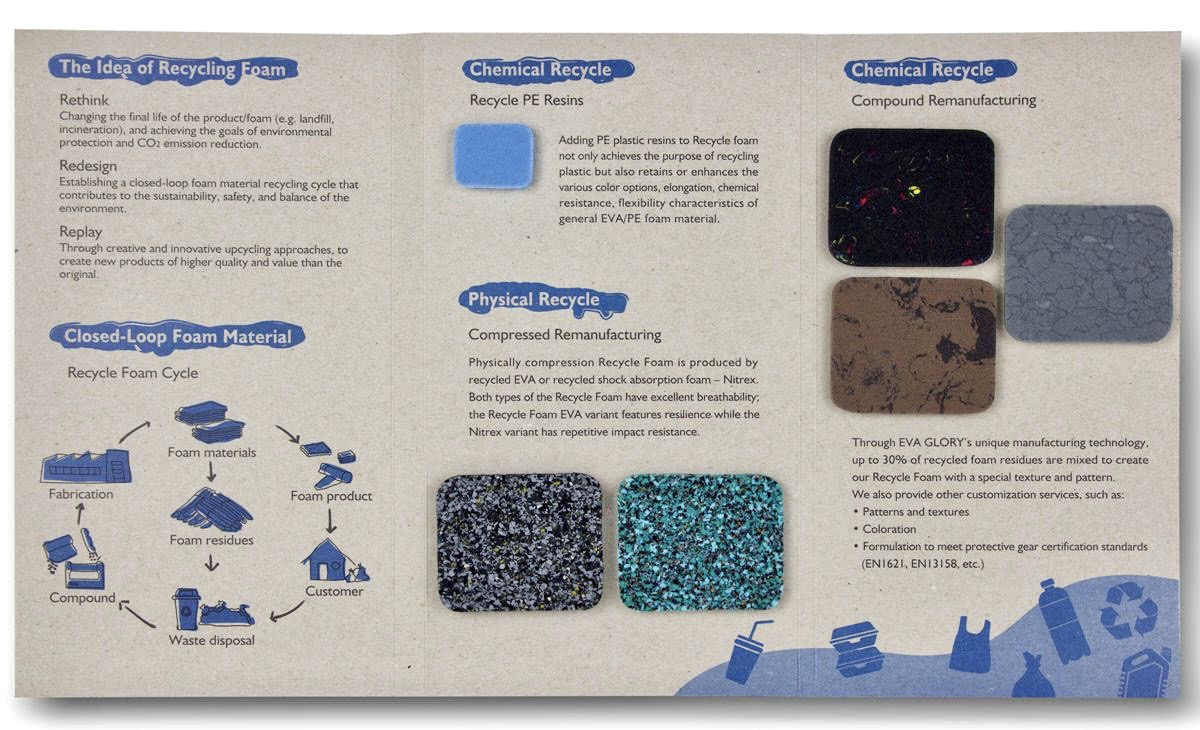

Recycling processes

| Technology | Type | Description and Features |

| Physical Recycle | Compressed Remanufacturing | Physically compression Recycle Foam is produced by recycled EVA foam or recycled shock absorbing foam - Nitrex. Both types of the Recycle Foam have excellent breathability; the Recycle Foam EVA variant features resilience while the Nitrex variant has repetitive impact resistance. |

| Chemical Recycle | Compound Remanufacturing | Through EVA GLORY's unique manufacturing technology, up to 30% of recycling foam residues are mixed to create our Recycled Foam with a special texture and pattern. We also provide other customization services, such as: ㆍPatterns and textures ㆍColoration ㆍFormulation to meet protective gear certification standards (EN1621, EN13158, etc.) |

| Recycle PE Resins | Adding PE plastic resins to Recycle foam not only achieves the purpose of recycling plastic but also retains or enhances the various color options, elongation, chemical resistance, flexibility characteristics of general EVA/PE foam material. |